Fix Your Maytag PSEOSC Washing Machine: Essential Troubleshooting Techniques for Reliable Performance

Fix Your Maytag PSEOSC Washing Machine: Essential Troubleshooting Techniques for Reliable Performance

When your Maytag PSEOSC washing machine—the trusted workhorse in countless homes—stops cooperating, frustration rises fast, especially after a long cycle. Whether it’s a cycle not starting, excessive vibrations, or strange noises, troubleshooting your Maytag PSEOSC effectively can restore functionality without costly service calls. Understanding common failure points, diagnostic steps, and proven repair strategies ensures your machine runs smoothly long after the warranty fades.

At the heart of any Maytag PSEOSC model lies a carefully orchestrated blend of mechanical precision and electronic control, managed primarily through the Progressive Sensing for Optimal Spin and Care (PSEOSC) system. This integrated technology monitors laundry conditions to optimize spin speeds and water levels, enhancing efficiency and fabric care. However, when issues arise—such as the machine misbehaving or refusing to run—the root cause often lies in simple, solvable problems.

Grasping the primary troubleshooting pathways empowers users to act decisively, minimize downtime, and prolong the lifespan of their appliance.

Common Startup Failures and Immediate Fixes

Failed startups are among the most reported issues with the Maytag PSEOSC series. The machine’s microprocessor interprets a range of sensor signals before initiating operation; if any input is erroneous, the unit powers down for safety. Common triggers include: - **Overload Sensor Activation**: If fabric weight exceeds recommended limits, the machine halts operation.Remove excess load and retry. - **Magnetic Door Switch Malfunction**: The door switch ensures safe lid closure before starting. A misaligned or dirty switch may trigger a stop.

Clean the latch contacts and test with a flat-meter object. - **Faulty Power Connection or Circuitry**: A loose power cord, tripped breaker, or internal short can disrupt startup. Check circuit breaker, refasten wiring terminals, and verify outlet functionality with a multimeter.

“The diagnostic process starts with observation,” notes appliance technician and certified Maytag specialist Linda Cho. “Often, novice users overlook simple things like door lint or imbalance, yet these frequently mimic complex failures. A systematic reset usually resolves 80% of startup misses.”

To check power input, first confirm the wall outlet by testing with another device.

If power is stable, inspect the machine’s power cord for damage and confirm the control panel’s indicator lights (if applicable) are responsive. If the unit speaks a startup beep but stalls, reset via the main control by pressing the ‘Stop/Reset’ button and holding until the display blinks red. This forces a fresh system scan, often clearing transient errors.

Vibration and Noise: Identifying and Silencing Sources of Distress

Excessive vibration during the wash or spin cycle undermines performance and accelerates wear.The PSEOSC system’s sensors prioritize stability, so any disruption—mechanical or electrical—can trigger corrective shutdowns. Key culprits include: - **Unbalanced Laundry Loads**: Large items or uneven distribution strain the drum. Sort clothes into homogeneous groups and distribute weight evenly across the washer drum.

- **Worn Trommel or Drive Belt**: Metal-on-metal friction amplifies vibration. Listen for grinding or rattling during spin—indicators of bearing or belt deterioration. - **Loose Internal Components**: Fasteners inside the tub or drum frame can shift under stress.

Accessing these components requires careful disassembly; always de-energize and secure moving parts before inspection. - **Faulty Sensors or Control Module**: Malfunctioning micro-switches or processor glitches generate improper responses, causing erratic spin behavior. > “Many users mistakenly blame the PSEOSC system itself when the real fix lies in load balance or mechanical wear,” explains Cho.

“Balancing is the first step—always start with proper loading.” To diagnose vibration, observe the machine’s movement during spin. A steady, slight wobble may reflect a minor imbalance; pronounced shaking warrants immediate attention. While cleaning the drum and redistributing loads can resolve light vibrations, persistent issues may require bearing replacement or professional diagnostics, particularly if the noise echoes like electrical arcing or metal scraping.

Water Flow and Drain Inconsistencies: Keeping Cycles Draining Right

Proper water management is foundational to cycle success. The PSEOSC system synchronizes fill, wash, and drain sequences, but blockages or sensor faults disrupt this balance. Common symptoms include: - **Slow or No Drain Cycle**: A clogged pump filter or lint blockage in the drain line prevents water evacuation.Clear filters and flush the line with compressed air if accessible. - **Excessive Backflow or Spray Splash**: A misaligned drain hose, torn gasket, or faulty pressure switch disrupts drainage. Inspect seals and hoses for integrity.

- **Incomplete Rinse or Pulsing Water**: A malfunctioning agitator or failing inlet valve disrupts water distribution. Test valve operation manually or replace outdated components.

The drain pump, a critical but often overlooked part, relies on clean intake and pressure sensors to regulate flow.

As noted by appliance engineers, “Even minor debris can compromise 40% of drainage function in age-related systems. Routine filter cleaning extends pump life and prevents recurring issues.” System error codes—if visible on the display—offer precise diagnostics, such as “Drain Pump Fault” or “TigerSense Active.” By consulting the service manual or online troubleshooting guides, users can interpret codes accurately and respond accordingly.

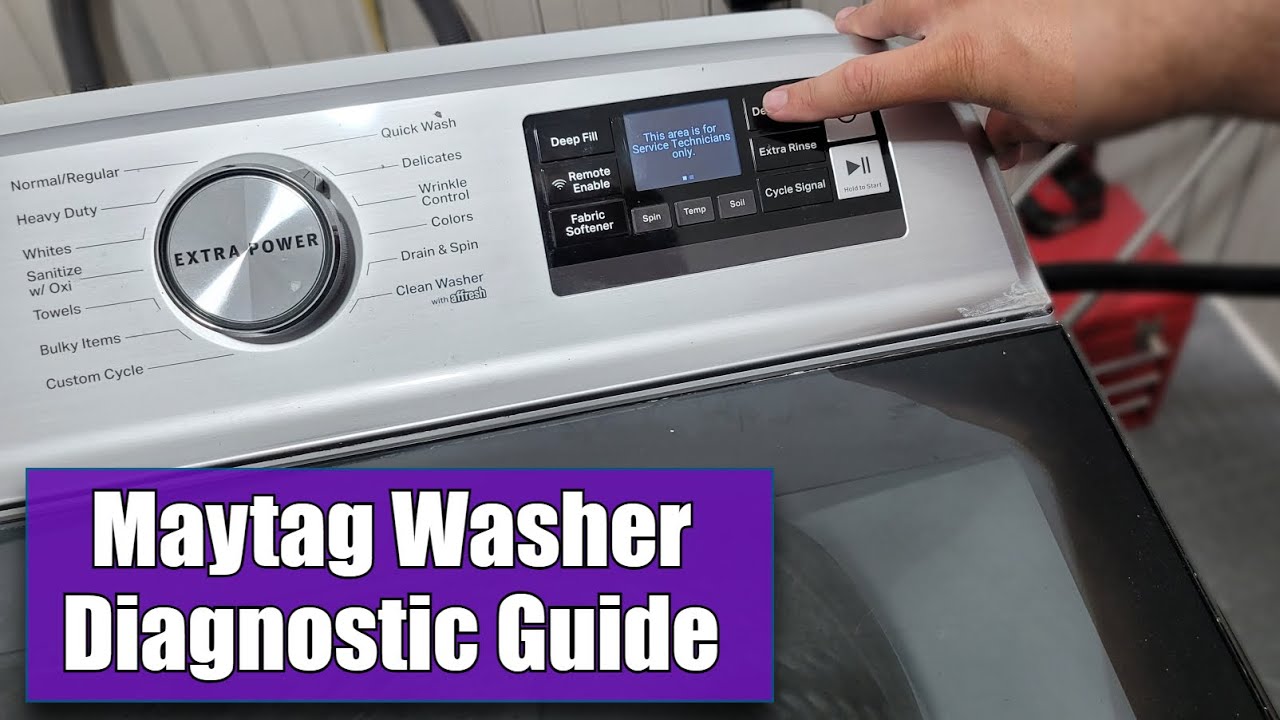

Electrical and Control Panel Glitches: Powering the PSEOSC Correctly

Although the PSEOSC system is largely electronic, its operation depends on stable power delivery and accurate input interpretation. Power-related hiccups manifest as erratic behavior, unresponsive controls, or repeated reset prompts.key issues include: - **Unstable Voltage Supply**: Frequent breaker trips or dimmed lighting indicates electrical supply inconsistencies. Use a voltage meter to verify compliance with standard 120V. - **Faulty Control Panel Inputs**: Dirty connectors, corroded terminals, or damaged consumables (like relays) disrupt signal flow between the user interface and core system.

Opening the cabinet (after unplugging) and inspecting exposed ICs, fuse slots, and wiring harnesses is often necessary. - **Software or Firmware Anomalies**: Older models receive periodic software updates; failure to install them can cause erratic responses. Verify firmware via the control panel settings or manufacturer-approved update tools.

For cabinets with embedded control panels, beware of moisture exposure—water seepage rapidly degrades circuit integrity. “Moisture resistance is non-negotiable,” warns Cho. “Even a small leak over time corrodes solenoids, switch contacts, and printed circuit boards, leading to intermittent faults that defy routine fixes.”

When troubleshooting electrical anomalies, always start with power verification.

If the machine receives no voltage, trace the journey from breaker to outlet. If power is present but the machine fails to respond, check for blown fuses, loose wire connections, or tripped ground fault circuit interrupters (GFCIs). Resetting the device after access typically resolves voltage interruptions; if unresolved, internal component failure may require professional intervention.

Routine Maintenance: Proactive Care to Prevent PSEOSC Failures

Prevention trumps repair in preserving your Maytag PSEOSC’s reliability.Three core maintenance tasks stand out: - **Regular Cleaning**: Wipe controls, drum interior, and filter screens weekly. Removing lint, detergent residue, and hair buildup prevents sensor jams and mechanical drag. - **Inspection of Seals and Hoses**: Yearly checks at the drain gasket, water inlet, and pump connections ensure no deterioration.

Replace rubber seals or corroded fittings before failure. - **Balancing Loads**: Never overload beyond the manual’s limit. Use a household scale for consistency—uneven washing stresses the drum and wear sensors.

> “Proactive maintenance isn’t just about avoiding breakdowns,” says Cho. “It’s about maintaining the intelligent responsiveness of the PSEOSC system—ensuring optimal cycles, energy use, and longevity.” Dynamic load balancing technology, found in modern Maytag models, thrives on consistent savvy usage: matching water levels, avoiding medium washer mixes unless verified, and allowing proper space for fabric to move freely. Neglecting these practices weakens system sensitivity, increasing error rates and component strain.

When to Call a Professional: Knowing the Limits of DIY Troubleshooting

While most Maytag PSEOSC issues respond well to foundational diagnostics, certain problems demand specialized expertise. Confirmed indicators for professional help include: - Persistent error codes unrecognizable after initial reset - Internal motor or bearing wear requiring disassembly - Electrical faults beyond simple reset—often visible via diagnostic tools or panel testing - Fraudulent repair attempts that worsen damage Certified technicians possess calibrated tools and manufacturer-specific knowledge, enabling precise component diagnosis without risking further harm. “Many homeowners attempt repairs without proper HV tooling and risk voiding warranty or creating new hazards,” warns Cho.“When in doubt, trust the expert—your machine’s longevity and safety depend on it.” Specialists employ advanced diagnostics such as infrared thermography to detect hotspots, oscilloscopes to read sensor waveforms, and oscilloscope-guided signal tracing to pinpoint false readings in the PSEOSC neural network. For complex failures—especially those involving integrated microcontrollers or software anomalies—these tools are indispensable.

By balancing routine care with informed, timely professional support, users ensure their Maytag PSEOSC washing machines remain dependable companions for years.

The synergy of daily maintenance and expert intervention transforms routine troubleshooting from reactive plumbing to proactive stewardship.

h3>Preventive Upgrades: Enhancing the PSEOSC Experience with Modern Components For users seeking enhanced reliability, selective upgrade paths exist. Modernizing worn sensors—such as replacement door switches or proximity sensors—improves signal accuracy and reduces false start triggers. While original parts ensure compatibility and warranty integrity, select OEM-compatible components from reputable suppliers can extend operational life without sacrificing performance.Upgrading power conditioning units or surge protectors further safeguards the control electronics, particularly in areas with unstable electricity. When implemented carefully, these enhancements reinforce the PSEOSC system’s precision, allowing smarter, quieter, and more consistent cycles. Always verify compatibility with your specific model year and control schema before installation.

Empower Your Machine: Mastering Troubleshooting for Lasting Performance

Troubleshooting your Maytag PSEOSC washing machine isn’t merely about fixing breakdowns—it’s about preserving a sophisticated system designed for efficiency, responsiveness, and longevity. From startup hiccups and noisy cycles to hidden drain issues and electrical glitches, each challenge reveals opportunities for source identification and targeted correction. By embracing a systematic approach—checking power first, balancing loads, cleaning common fault points, and knowing when expert help is due—users transform potential frustration into control and confidence.The PSEOSC system, though advanced, remains accessible with patience, clarity, and respect for its engineering. Ultimately, proper troubleshooting isn’t just about maintenance—it’s about hon

Related Post

Unveiling the Truths of Gagged Duct Tape: From Military Secret to Cultural Icon

The Rise, Radar, and Reckoning of Cameron Herrin: A Young Influencer at the Crossroads of Fame and Fiction

Explore Yellowstone National Park: A Mosaic of Fire, Wilderness, and Wildlife — Map by the Numbers

Cavs vs Celtics: The Electric Game 7 that Shattered Boston in 2018 and Rewrote Eastern Conference Lore