From Lever to Innovation: How Simple Machines Revolutionized Human Progress

From Lever to Innovation: How Simple Machines Revolutionized Human Progress

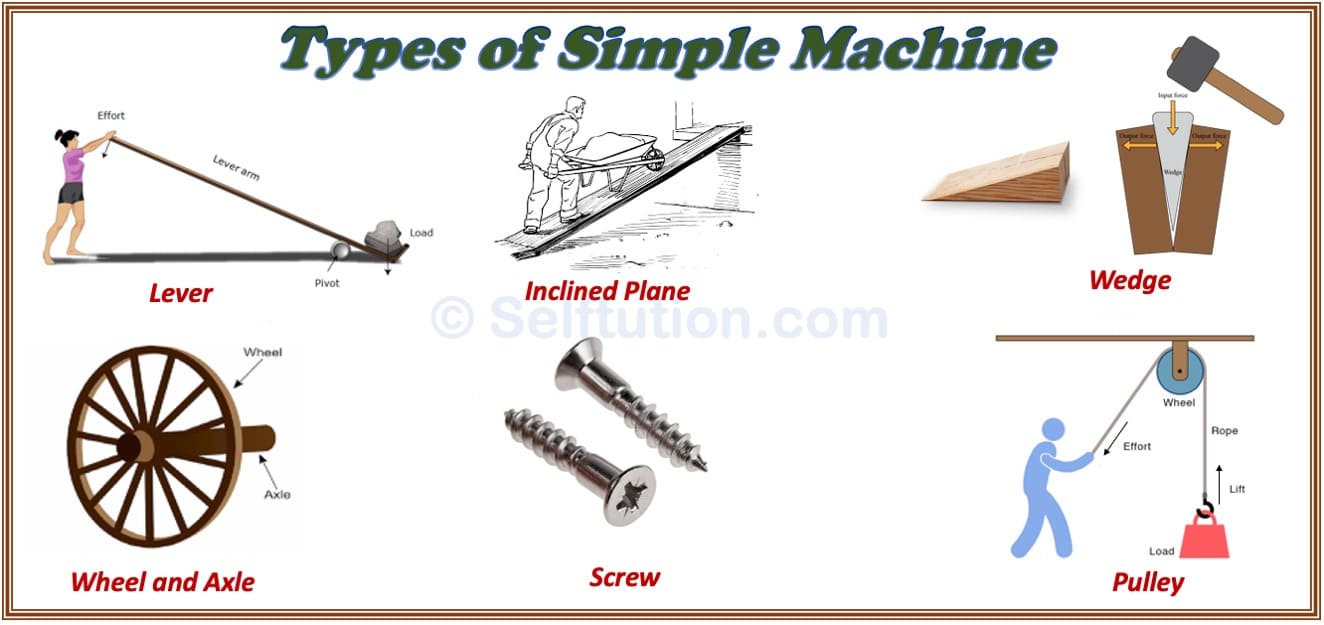

From ancient Egypt to modern robotics, simple machines form the bedrock of engineering and daily life, enabling humans to multiply force, change direction, and overcome physical limits with remarkable efficiency. Lever mechanics, one of the earliest understood simple machines, illustrate fundamental physical principles that remain essential in both ancient tools and cutting-edge technology. These devices—pulleys, inclined planes, levers, wheel and axles, screws, and wedges—transform effort according to the laws of energy and force, embodying centuries of scientific insight.

Understanding how the science behind simple machines shaped human advancement reveals not just historical achievements, but ongoing engineering brilliance that continues to power innovation.

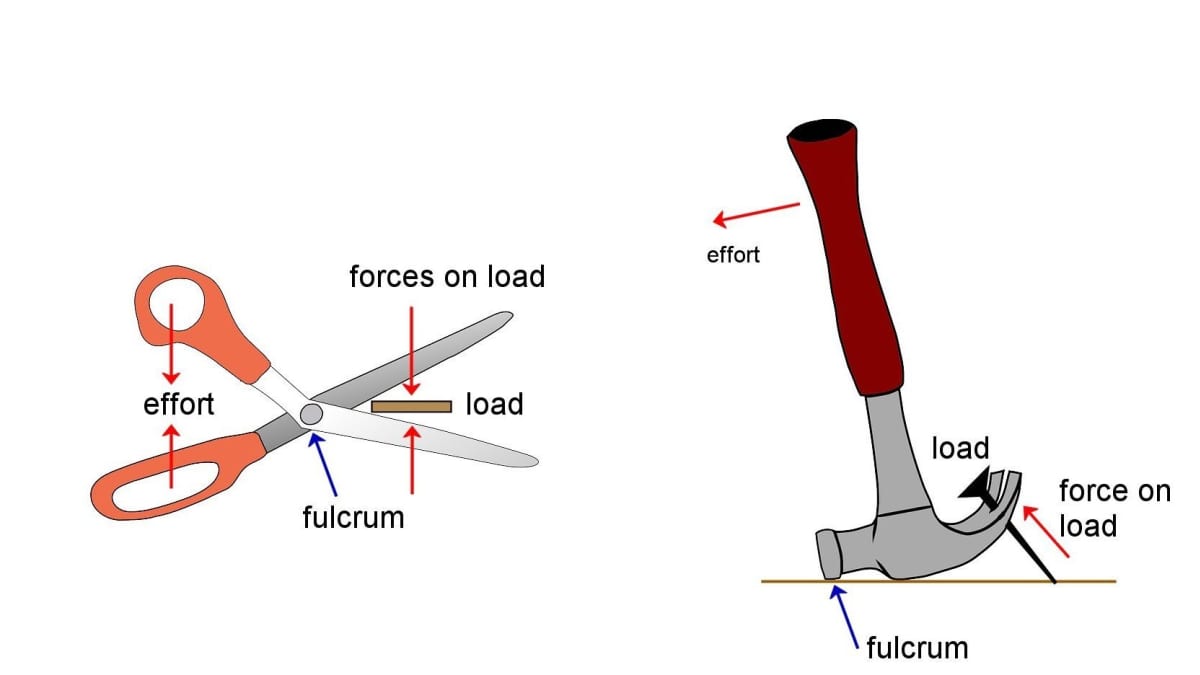

At the heart of Lever: The Science Behind Simple Machines lies a profound simplicity: a rigid bar pivoting on a fulcrum to amplify input force. The Massachusetts Institute of Technology’s engineering curriculum defines this core interaction as a mechanical advantage system, where force multiplication follows a precise mathematical relationship—selector of the lever’s effort placement determines how much input is required to lift a load.

As physicist Richard Feynman once noted, “Good design is this: divide the labor, exploit mechanics, and everything becomes easier,” a principle instinctively mastered by ancient engineers. The Five Classical Simple Machines

The five classical simple machines — levers, wheels and axles, pulleys, inclined planes, and screws — each manipulate physical forces in distinct ways:

For example, in a crowbar, placing the fulcrum close to the load allows minimal push to move massive nails or logs.

In construction, block and tackle pulley systems reduce crane operator strain significantly.

Each machine operates within the framework of energy conservation, though not without trade-offs.

While they reduce force, most multiply output distance—aligned with the principle that “you trade strength for speed or range,” as noted in historical engineering texts.

Profile: The Lever’s Role in Invention and Industry

The lever stands not only as a basic learning tool but as a foundational enabler of technological leaps. Its presence cuts across civilizations: Egyptian architects used long levers to position massive stone blocks during pyramid construction.

Medieval blacksmiths employed levers in bellows and cranes, while steam-powered industry harnessed lever-driven mechanisms in engines and manufacturing equipment. Today, lever principles persist in ergonomic design—from child safety seats to crowbars—proving their enduring utility. Geometric ratios define lever performance.

The mechanical advantage equals the ratio of the effort arm (distance from fulcrum to input) to the resistance arm (distance from fulcrum to load). For instance, a crowbar with a 4:1 effort arm to 1:1 resistance arm provides four times the force per push, turning inevitable torque into manageable labor. This simple math underpins safe and effective engineering solutions worldwide.

Real-World Applications Active Today

Modern engineering continues to draw inspiration from simple levers and related machines. Robotic manipulators use torque and leverage analogs to mimic human arm movements with precision and strength. Medical devices like surgical forceps and orthopedic tools rely on lever mechanics to apply controlled pressure with minimal strain.

In consumer goods, bottle openers, bottle racks, and even kitchen scales embody everyday lever design principles. Industrial and Infrastructure Impact Factory automation solves labor-intensive lifting through lever-driven conveyors, presses, and automated arm systems—turning repetitive industrial tasks into efficient, safe operations. Even massive infrastructure projects, such as bridge assembly, integrate scaling principles: massive cranes act as long-arm levers to lift and position tons of steel with millimeter accuracy.

The principles of mechanical advantage are routinely optimized in computer-aided design software, ensuring that every lever-based mechanism meets strict performance criteria.

Educational Insights: Teaching Levers to Understand Mechanics

Understanding levers demystifies physics for students and future engineers. By using hands-on experiments—lever bracing with rulers and fulcrums—learners internalize force relationships and fulcrum positioning.

Virtual simulations further illustrate how altering arm lengths recalibrates force requirements, turning abstract equations into tangible experiments. This tactile, visual approach fosters deeper comprehension of physics in action, transforming classrooms into laboratories of mechanical discovery.

Leveraging Levers in Sustainable Design

In the era of sustainability, lever mechanics offer low-energy solutions to modern challenges.

Human-powered tools powered by optimized levers require minimal input to achieve high output, reducing reliance on energy-intensive motors. From pedal-activated generators to hand-cranked water pumps, lever-based systems exemplify efficient resource use, merging ancient wisdom with contemporary environmental goals. Engineers today rediscover the elegance of these machines not just for strength, but for reduced ecological footprint.

The Enduring Legacy of Simple Mechanics

Lever: The Science Behind Simple Machines reveals a continuous thread of innovation woven through human history—from grain mill grinding by water-driven levers to robotic arms using calibrated torques. These machines are not relics, but living blueprints of problem-solving ingenuity. By adhering to the fundamental physical principles they embody—force multiplication, energy conservation, and mechanical advantage—simple machines empower progress across industries, education, and sustainability.

As long as humans seek to harness nature’s forces with precision and simplicity, the lever and its kin will remain indispensable, proving that sometimes, the smallest mechanisms drive the largest changes.

Related Post

Voice Actor Of Iroh: The Timeless Soul Behind One of Animation’s Most Revered Mentors

DEBUG: “Situs Ini Tidak Dapat” – Dijangkau 6 Unmatched Strategies to Overcome Legal & Technical Barriers

Seattle Craigslist’s 5 Car Parts Predictions That Will Blow Your Mind — Don’t Miss What’s Coming Next

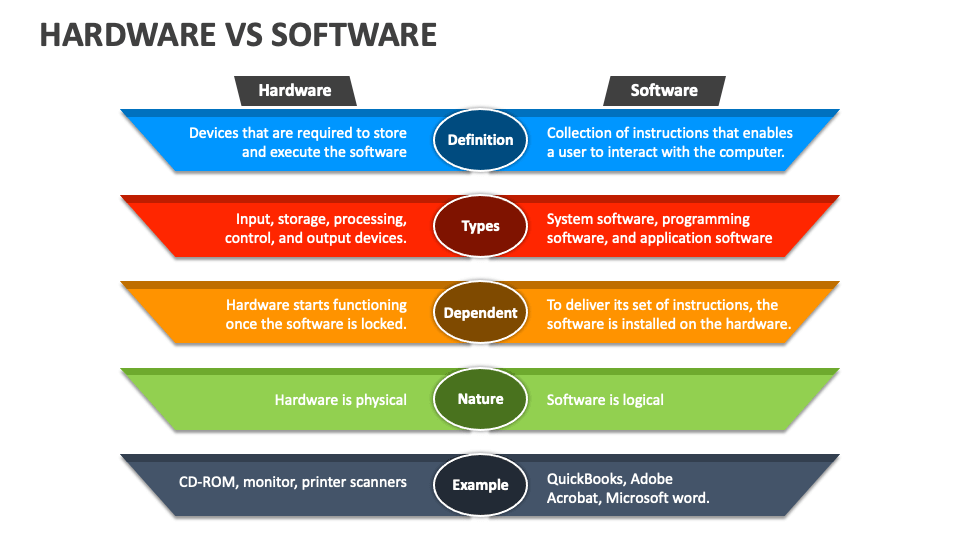

Software Vs. Hardware: The Core Battle That Defines Your Computer’s Performance