How to Calculate K: The Precision Tool Transforming Modern Analytics

How to Calculate K: The Precision Tool Transforming Modern Analytics

In enterprise data ecosystems, few metrics carry the weight of K — a precise ratio central to assessing performance, forecasting trends, and guiding strategic decisions. Often overlooked but fundamentally powerful, K offers a clear lens through which organizations evaluate efficiency, quality, and scalability. Whether applied in manufacturing yield analysis, marketing campaign response, or IT system reliability, calculating K correctly transforms raw data into actionable intelligence.

This article demystifies the core mechanics of calculating K, revealing why it matters and how to master its use.

Understanding the Definition and Significance of K

The K statistic, short for “Key Ratio,” quantifies the relationship between two critical performance indicators: measurable output and targeted benchmarks. At its core, K measures how effectively an organization or process delivers value relative to its goals.It is not merely a number but a diagnostic tool that reflects operational health. As industry experts note, “K distills complexity into clarity — it’s the single metric that cuts through noise to highlight where performance excels or lags.” This makes K indispensable in quality control, process optimization, and predictive modeling across sectors like supply chain logistics, healthcare operations, and software development. K’s significance extends beyond mere measurement — it drives accountability.

When K falls below a predefined threshold, it signals inefficiencies demanding immediate attention; when it improves steadily, it validates process enhancements and technological investments. Unlike broader KPIs, K’s focused nature ensures decision-makers see only what matters, avoiding dilution of insight.

The Universal Formula for Calculating K

The mathematical foundation of K is deceptively simple yet powerful: **K = (Actual Performance) / (Target Benchmark)** This ratio—always dimensionless—expresses output relative to aspiration.A K of 1.00 indicates perfect alignment; above 1.00 signals superior performance, while below 1.00 exposes gaps. The precision of this formula lies in its clarity: both numerator and denominator must reflect the same unit and time frame for meaningful comparison. For example, measuring K in customer resolution time requires both input (time spent resolving tickets) and output (number resolved) in consistent units and period.

The formula applies across domains: - In production, K = units produced / (ideal output capacity × (1 – defect rate) - In marketing, K = total conversions / (clicks × target conversion goal) - In IT, K = uptime minutes / (total scheduled operational hours) Understanding this structure enables analysts to adapt K to their specific context without sacrificing accuracy.

Step-by-Step Guide to Accurately Calculating K

Calcultating K with rigor begins with three critical steps that eliminate error and ensure consistency. **First, define clear, measurable inputs and targets.** Before computation, identify the exact metrics: what exactly represents output (e.g., units produced, sales closed), and what constitutes the target benchmark (e.g., maximum allowable downtime, quota for conversions).Without this clarity, K becomes ambiguous and misleading. **Second, collect synchronized, reliable data.** Data integrity is non-negotiable; even minor inaccuracies distort K. For instance, if a manufacturing process targets 1,000 units daily but records output as 980 due to measurement error, K will falsely suggest inefficiency.

Use automated systems where possible, cross-verify records, and audit inputs regularly. **Third, apply the formula consistently over time.** Calculating K isn’t a one-off exercise — it requires periodic analysis to track trends. Monthly or quarterly K assessments reveal patterns that isolated snapshots miss.

For example, a K rising from 0.92 to 1.05 over three quarters confirms meaningful improvement, not random fluctuation. Organizations that embed these steps into their analytical workflow cultivate a data-driven culture where decisions are grounded in verified insight rather than intuition.

Real-World Applications of K Across Industries

In supply chain management, K acts as a real-time health check for logistics efficiency.A global distributor might use: **K = (On-time deliveries) / (total shipments)** Monitoring K monthly identifies bottlenecks—such as carrier delays or warehouse congestion—enabling targeted corrective action. A K maintaining above 95% directly correlates with customer satisfaction and reduced operational risk. In marketing, K refines campaign strategy by measuring conversion effectiveness: **K = (Qualified leads generated) / (campaign budget spent)** Here, K reveals ROI per dollar invested.

When K exceeds industry benchmarks—say, 4:1 instead of the 3:1 norm—it validates messaging and channel choices, empowering reallocation of marketing spend. In healthcare, K ensures patient flow propriety: **K = patients seen per hour / staff hours available** Hospitals use this to optimize staffing schedules, reducing wait times and improving care quality. A sudden drop in K during flu season signals understaffing, prompting swift adjustment.

Across sectors, K transforms qualitative goals into quantifiable outcomes, enabling precision targeting across complex systems.

Numerical Examples to Illustrate K Calculation

Understanding K through concrete examples clarifies both its purpose and application. **Manufacturing Example:** A factory targets 2,500 widgets daily, with a 3% defect rate.Actual output: 2,375 units (2,500 × 0.97). K = 2,375 / (2,500 × 0.97) = 2,375 / 2,425 ≈ 0.9796 → or approximately 97.96

Related Post

Unlock the Power of Ka: How Precise pKa Values Reveal Glribing Ka from pH

Khabib and Hasbulla’s Unbreakable Bond: A Blueskin Connection Woven in Solidarity and Silence

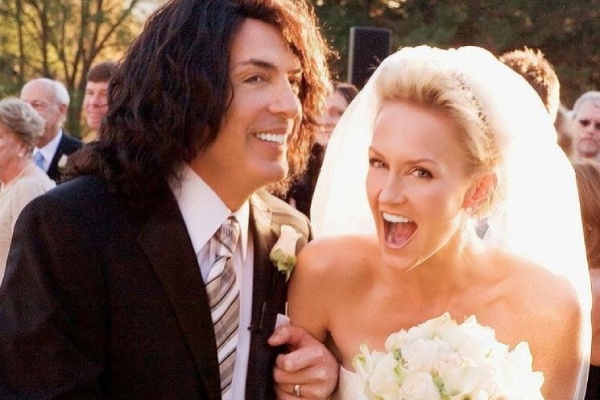

Paul Stanley’s Wife Speaks Out: The Age of Erin Sutton Revealed in a Five-Year Unveiling

RaquelPedraza Redefines Public Advocacy: How One Voice Shapes Global Discourse