In Just Five Inches: How Precision Shapes Our World

In Just Five Inches: How Precision Shapes Our World

From the tight tolerances of aerospace engines to the compact design of smartphones, the world hinges on measurements so precise they are nearly invisible—but profoundly impactful. In just five inches, every dimension, every offset, and every fit is calibrated with microscopic precision to ensure performance, safety, and reliability. The human eye may not perceive changes smaller than a fraction of an inch, but engineers rely on exact centimeters and sub-millimeter accuracy to define success.

In industries like aviation, medical devices, and consumer electronics, five inches can represent a sea of opportunity—or a critical failure point. Understanding how this compact space governs functionality reveals the intricate dance of design, manufacturing, and innovation.

Modern manufacturing thrives on micron-level control within tight spatial constraints.

In aerospace, turbine blades in jet engines are often only a few centimeters long but must withstand extreme heat and pressure, requiring dimensional accuracy to within 0.01 inches. This level of precision ensures airflow efficiency, fuel economy, and engine longevity. Similarly, in medical devices such as minimally invasive surgical tools, internal channels may measure just five inches long—small enough to navigate through delicate pathways yet large enough to house sensors, guidewires, or drug delivery systems.

A single deviation of 0.005 inches could cause obstruction, risking patient safety. Thus, manufacturing within such constrained dimensions demands advanced metrology, precision machining, and automated quality control systems capable of real-time feedback.

Design Standards and Industry Standards Define Five Inches

Engineers rely on meticulously defined design standards to govern every millimeter—and even fraction within five inches. These standards vary by sector but share a core principle: consistency and precision.In the automotive industry, for example, steering column assembly lengths are typically calibrated within ±0.1 inch tolerances to guarantee reliable driver input and airbag deployment timing. For consumer electronics, touchscreen bezels often maintain a fixed 5-inch internal diagonal across device lines—enabling seamless integration with software interfaces and user ergonomics. Industry standards bodies like ISO, ASME, and AMS play a crucial role by establishing calibration protocols and dimensional limits.

A 2023 report from the International Organization for Standardization emphasizes the necessity of “seven-sigma quality” in systems where tolerances are measured in inches, ensuring product lifecycle reliability. “In a five-inch space, each micrometer counts,” notes Dr. Elena Torres, senior mechanical standardization engineer at ASME.

“Small variations compound across component interactions, threatening system integrity.” Such standards anchor innovation, providing a unified language for design, fabrication, and testing across global supply chains.

Consider smartphone cameras: modern flagships feature lenses and image sensors spanning internal dimensions under five inches—yet deliver multi-megapixel resolution and optical zoom. The camera module’s tolerance stack includes lens spacing precision within ±0.02 inches and sensor alignment accurate to 0.001 inches. This precision enables features like computational photography and low-light performance that define user experience.

Equally critical: mounting brackets and connectors must fit perfectly—any misalignment risks signal loss or device failure. The tight integration within five inches exemplifies how spatial constraints drive cutting-edge engineering and global collaboration in manufacturing.

Challenges of Precision in Compact Spaces

Working within five inches presents unique engineering challenges, especially when complying with stringent tolerances. Thermal expansion, material deformation under stress, and mechanical flexing all threaten dimensional stability.A component assembled to 5 inches at room temperature may shift by up to 0.005 inches when exposed to operating temperatures exceeding 150°C—enough to disrupt tight tolerances. To address this, engineers employ materials with matched coefficients of thermal expansion, such as aluminum alloys and engineered plastics, reducing unpredictable dimensional drift. Another challenge is achieving simultaneous precision across multiple axes.

A five-inch device housing multiple components—gears, wiring, sensors—must maintain dimensional harmony without interference. Assembly processes like robotic spindle machining and laser interferometry enable micron-level alignment, ensuring every part fits as intended. “Precision isn’t just about measuring—it’s about designing with the entire assembly in mind,” explains Michael Chen, lead engineer at a leading medical device firm.

“Tight integrations mean even a 0.01-inch offset in one part can cause failure downstream. That’s why simulation tools and real-time metrology are indispensable.” Advanced error compensation software further mitigates risk by adjusting manufacturing parameters on the fly, maintaining tight control across compact systems.

Quality control today hinges on automated inspection systems capable of verifying five-inch components at line speed with near-perfect accuracy. Optical CMMs (coordinate measuring machines), laser scanners, and vision-guided robots inspect geometry, surface finish, and alignment—all within fractions of an inch.

This shift to automation not only improves consistency but accelerates feedback loops, allowing rapid design iterations and reduced time-to-market. In industries where failure is not an option, such precision is not a luxury—it is foundational.

Real-World Applications: Five Inches Powering Innovation

In aerospace, five-inch actuator housings control critical flight surfaces, demanding both miniaturization and durability. In medical robotics, compact end-effectors fit within five-inch shafts, enabling minimally invasive procedures with sub-millimeter control.Consumer devices, from wearables to gaming controllers, leverage five-inch form factors to balance ergonomics, button placement, and internal circuitry—enhanced by precise fit between housing and components. Take smartwatches as a prime example: internal battery, display, and sensor modules occupy just a few inches, yet enable fitness tracking, ECG monitoring, and contactless payments. Similarly, 5-inch medical laparoscopes use miniature optics and motorized actuators to navigate human anatomy safely, where every millimeter affects visibility and maneuverability

Related Post

All Us Towing Columbia SC: Your Trusted Partner for Speed, Reliability, and Top Service

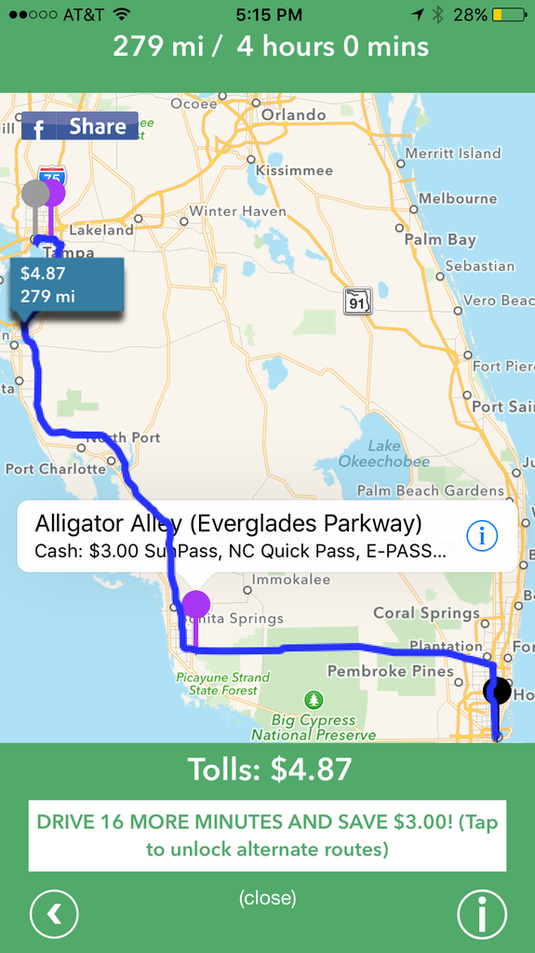

Florida Tolls Your Guide to Understanding the State’s Critical Transportation Network

Pastor Juan Carlos Harrigan Ignites Spiritual Renewal Across Faith Communities in 2022

Unveiling the Truth Behind the Lamotogirl Leak: Secrets, Scandal, and Surveillance