Power SCADA Operation In 2020: Mastering Industrial Automation with Precision

Power SCADA Operation In 2020: Mastering Industrial Automation with Precision

In 2020, Power SCADA systems emerged as critical nerve centers for industrial operations, enabling real-time monitoring, data integration, and automated control across energy, manufacturing, water, and infrastructure sectors. With growing demands for operational resilience and digital transformation, SCADA—short for Supervisory Control and Data Acquisition—evolved beyond traditional monitoring into a sophisticated platform orchestrating complex industrial ecosystems. This guide distills the essentials of Power SCADA operation in 2020, exploring its architecture, core functions, deployment strategies, and transformative impact amid a rapidly shifting technological landscape.

Unpacking Power SCADA: Architecture and Core Components

At its core, Power SCADA operates as a distributed control system integrating acquisition hardware, communication networks, and human-machine interfaces (HMIs).

The system’s architecture typically includes remote terminal units (RTUs) and programmable logic controllers (PLCs) deployed at field sites, which collect sensor data and execute local control functions. Centralized servers process incoming signals, analyze trends, and present actionable insights via HMIs and dashboards.

The system integrates legacy industrial protocols—such as Modbus, DNP3, and OPC UA—with modern Ethernet and wireless networks, enabling seamless data exchange. Real-time telemetry, command execution, and historical data logging are foundational capabilities.

diferencia of Power SCADA, particularly in 2020, was its enhanced cybersecurity framework, designed to safeguard grid stability and industrial processes against evolving cyber threats.

Key Elements of Power SCADA Architecture

- Field Devices → RTUs/PLCs: Collect sensor inputs (temperature, pressure, flow) and transmit control signals.

- Communication Layers: Utilize wired (fiber, Ethernet) and wireless (radio, cellular) mediums, robustly designed for reliability under harsh conditions.

- Central SCADA Server: Aggregates, processes, and correlates data; runs analytical algorithms and flags anomalies.

- Human-Machine Interface (HMI): Graphical dashboards allow operators to visualize processes, adjust parameters, and initiate manual or automatic operations.

- Cybersecurity Modules: Firewalls, intrusion detection, secure remote access, and role-based access controls ensure data integrity and system availability.

Operational Workflow: From Data Collection to Action

Power SCADA systems follow a dynamic operational lifecycle, starting with continuous data acquisition—every millisecond matters in high-stakes environments. Operators rely on precise, synchronized inputs from remote sites to monitor critical parameters in real time, enabling immediate responses to deviations or emergencies.

The operational workflow has several interlocking phases:

- Data Ingestion: Sensors and field devices stream live measurements to RTUs, which format and forward data via secure communication channels.

- Processing and Analysis: The central server applies rule-based logic and advanced analytics—such as predictive maintenance models and trend forecasting—to detect patterns or irregularities.

- Visualization & Response: HMIs present intuitive visualizations—trend graphs, alarm lists, sweep maps—supporting rapid diagnostic and control decisions.

- Automation & Control: SCADA can autonomously adjust actuators or trigger predefined control sequences upon detecting critical thresholds, minimizing human latency.

2020 saw increased integration of edge computing within SCADA networks, enabling faster local processing and reduced reliance on distant servers—particularly vital in remote or remote-connected facilities.

Real-World Applications and Industry Use Cases

Across sectors, Power SCADA systems delivered measurable improvements in efficiency, safety, and compliance. In the energy space—specifically power generation and grid management—SCADA enabled precise control of turbines, transformers, and distribution networks.

For example, utility operators leveraged SCADA to balance load fluctuations during fluctuating demand periods, improving grid reliability and reducing outage durations.

Manufacturing facilities deployed SCADA to monitor assembly lines, quality control sensors, and inventory systems, achieving tighter process control and reduced downtime. Water treatment plants used SCADA for automated dosing, reservoir monitoring, and pump control, ensuring regulatory compliance and resource efficiency. Utilities in flood-prone regions utilized SCADA’s flood-risk modeling and remote valve management to trigger emergency responses swiftly.

Technological Advancements Driving SCADA in 2020

The year 2020 accelerated the infusion of cutting-edge technologies into SCADA, transforming these systems from passive monitoring tools into proactive operational intelligence platforms.

Cloud Integration: Many operators migrated parts of their SCADA infrastructure to public or hybrid cloud environments, enabling scalable data storage, advanced analytics, and remote access capabilities. Cloud-based SCADA solutions reduced capital expenditures while supporting rapid deployment across geographically dispersed sites.

Artificial Intelligence and Machine Learning: AI-driven analytics began appearing in mainstream SCADA deployments, identifying subtle process deviations before they escalated into failures. Predictive maintenance algorithms reduced unplanned downtime by forecasting equipment wear and optimizing maintenance schedules.

Enhanced Cybersecurity Measures: With rising cyber threats targeting critical infrastructure, Power SCADA systems in 2020 integrated advanced cybersecurity protocols: zero-trust architectures, real-time threat intelligence feeds, encrypted communications, and automated incident response workflows.

These measures reinforced system resilience against ransomware, phishing, and external breaches.

Interoperability and Open Standards: Adoption of OPC UA and IEC 61850 standards improved cross-vendor compatibility, enabling seamless integration of SCADA with enterprise systems like ERP, MES, and CMMS—streamlining data flow and eliminating silos.

Challenges in SCADA Operations Amidst Rapid Digitalization

Despite its promise, Power SCADA implementation in 2020 was not without hurdles. Operators faced significant challenges in balancing innovation with operational continuity.

Integration complexity emerged as a major concern: legacy equipment often spoke incompatible protocols, requiring costly gateways, protocol converters, or phased modernization efforts.

Training staff to navigate increasingly sophisticated HMIs and analytics tools demanded robust upskilling programs and change management strategies.

Cybersecurity tensions persisted, with sophisticated attacks targeting SCADA systems through supply chain vulnerabilities and zero-day exploits. Organizations had to invest continuously in patching, threat detection, and employee awareness. Regulatory compliance—especially under frameworks like NERC CIP for energy—added additional layers of documentation and audit requirements.

Reliability remained paramount; downtime in SCADA systems could cascade into operational paralysis.

Ensuring resilient communication networks, fail-safe control logic, and redundant hardware became essential in mission-critical environments.

Best Practices for Optimizing Power SCADA in 2020

To maximize performance and security, infrastructure managers adopted several proven strategies during 2020:

- Phased Modernization: Gradually upgrading components minimized disruptions, allowing incremental testing and staff adaptation.

- Zero-Trust Security Instantiation: Enforcing strict access controls, multi-factor authentication, and continuous monitoring fortified cybersecurity defenses.

- Redundant Communication Paths: Dual-network architectures ensured connectivity continuity during outages, improving system availability.

- Regular Audits and Training: Routine vulnerability assessments and hands-on operator training enhanced readiness for incidents and system updates.

Real-time performance dashboards also allowed proactive tuning—detecting performance bottlenecks like high-latency data transfers or HMI responsiveness issues before they impacted operations.

Automation workflows were paired with clear escalation protocols, ensuring that human oversight complemented AI-driven decisions, preserving accountability and system transparency.

The Transforming Role of SCADA in Industrial Resilience

By 2020, Power SCADA had evolved into more than a control system—becoming the backbone of digital industrial resilience. Organizations that harnessed its full capabilities achieved unprecedented levels of process visibility, operational agility, and risk mitigation. The convergence of real-time data, intelligent analytics, robust cybersecurity, and interoperable platforms positioned SCADA at the heart of the Industry 4.0 revolution, enabling industries to anticipate challenges, optimize performance, and sustain continuity in an increasingly volatile world.

As digital transformation accelerated, the lessons learned in 2020 solidified SCADA’s role as indispensable infrastructure for modern industry.

With strategic deployment, continuous innovation, and a human-centered approach, Power SCADA emerged not just as a technology for monitoring—but as a catalyst for smarter, safer, and more efficient operations across global markets.

Related Post

Decoding Alert and Oriented X1: The Brainwave signal Shaping Human-Machine Synergy

Dave and Busters Auburn WA: Where Entertainment Meets Innovation in Central Washington

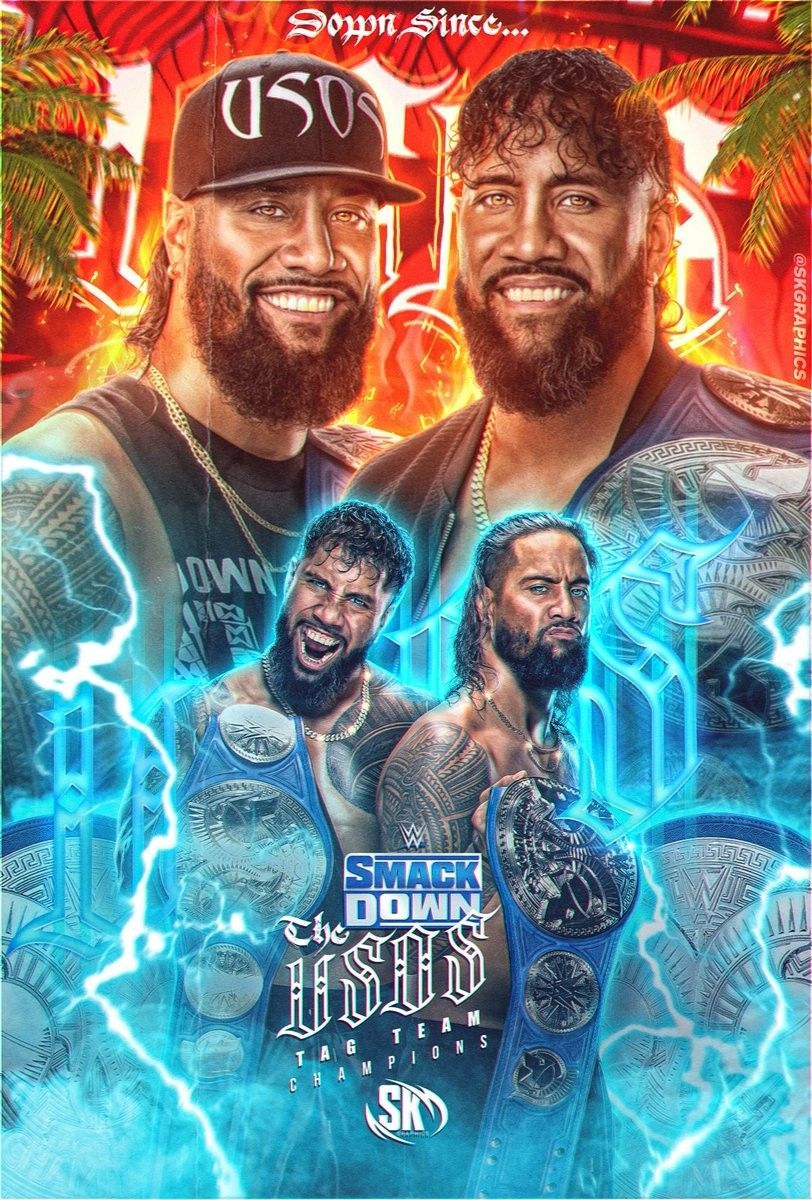

Jey Uso and The Rock: The Unbreakable Bond That Redefined Family and Legacy in WWE

UFO Crash in Arizona: Real or Revelation? Decoding the Truth Behind the Almedio Aerial Incident