Wall Anchor Problems: Why It’s Not Holding & the Fixes That Actually Work

Wall Anchor Problems: Why It’s Not Holding & the Fixes That Actually Work

When a wall anchor fails—twisting, cracking, or simply refusing to set—homeowners and contractors face frustration, costly repairs, and compromised safety. These anchors, critical for securing furniture, shelves, or structural elements, are often expected to deliver permanent reliability, yet common installation flaws, material incompatibility, and environmental stress frequently undermine their performance. Understanding the root causes behind wall anchor failures—and implementing targeted, evidence-based fixes—is essential for both DIY enthusiasts and professionals aiming to ensure long-lasting, secure installations.

Wall anchors serve as the unsung heroes of interior and construction projects, transferring lateral and vertical loads from fasteners into masonry, drywall, or concrete. Despite their small size, their role is monumental. However, their performance is inherently tied to precise installation, material compatibility, and the physical properties of the substrates they interface with.

“Most failures stem not from poor-quality anchors, but from improper use—driving screws too hard, choosing the wrong anchor for the surface, or ignoring load-bearing limits,” explains structural engineer Dr. Elena Torres.

Common Causes of Wall Anchor Failures

Incorrect Anchor Type for the Material

One of the most frequent oversights is selecting an anchor that mismatches the wall’s composition. For instance, plastic expansion anchors used in drywall rarely bond effectively in dense concrete or brick.Similarly, metal toggle bolts performed poorly in soft, crumbly plaster, where insufficient grip causes pull-out. The anchor must match the substrate’s hardness, density, and load requirements. The American Society for Testing and Materials (ASTM) standards emphasize matching anchor performance ratings to specific materials—yet many installations bypass these guidelines.

- Material incompatibility: Anchors rated for light drywall (typically 50–100 lbs load) are easily overwhelmed by heavier fixtures or floor-mounted units exceeding 200 lbs.

- Driving errors: Overdriving screws compresses the anchor, reducing expansion and bonding, especially in soft or porous surfaces.

- Substrate degradation: Cracks, flaking paint, or loose materials weaken the anchoring interface before installation, even with correct tools.

- Moisture and expansion: In humid or fluctuating environments, moisture absorption expands masonry, cracking anchors that lacked flexibility or moisture resistance.

Setting Techniques That Save Structural Integrity

Even the best anchor fails without proper setup. The sequence and precision of installation fundamentally determine long-term holding power. Poorly drilled holes compromise anchor expansion, while insufficient pressure during installation limits contact with the material.

A 2023 study by the National Institute of Building Sciences found that 68% of anchor failures stem from inadequate driving technique and lack of torque control.

Best practices include: - Using a chisel to create precise, properly sized holes—avoiding over-drilling or under-drilling—and selecting the correct bit size. - Driving anchors slowly and steadily, feeling for full resistance before fully tightening to ensure full expansion.

- Applying even pressure, especially in brittle materials, to prevent micro-cracks that degrade grip. - For toggle bolts or sleeve anchors, ensuring the wing expansion fully locks into the subsurface—ideally requiring 3–5 full revolutions of a specific tool.

Effective Fixes for Compromised Wall Anchors

When an anchor has failed—whether pulling out, cracking, or showing signs of stress—the first step is assessing damage depth and surrounding material integrity.For minor gaps or partial pull-outs, simple repairs can restore stability.

Repairs often involve: - Removing damaged anchors carefully using a puller tool to avoid further wall damage. - Cleaning and priming the hole, using appropriate adhesive compatible with drywall, concrete, or masonry.

- Selecting a superior replacement anchor—matching load specs and material—then installing with reinforced doweling (e.g., inserting a metal sleeve before the expansion). - For concrete or brick, injecting anchor grout into pre-drilled holes enhances bonding and distributes stress more evenly. 经验证ated fix inspired by contractor best practices: “When anchoring through drywall to studs, I always use a long toggle anchor with galvanized metal, install a ridge board for lateral support, and torque the screw to 3.5–4.5 foot-pounds—this prevents cracking and ensures even load transfer.” — Marcus Delgado, licensed contractor with sixteen years in residential renovation.

Preventive Measures for Lifelong Stability

Prevention remains the most cost-effective strategy. Prior to installation, verify wall composition and load needs using ASTM compatibility charts. Use a levels and stud finders to confirm framing alignment.

Drill pilot holes progressively—starting shallow, then enlarg

Related Post

Virginia Social Impact Pioneer Caroline Fentress: Transforming Communities Through Purpose-Driven Innovation

Big Brother VIP Albania 4: Your Ultimate Guide to 24/7 Live Access and Behind-the-Scenes Intimacy

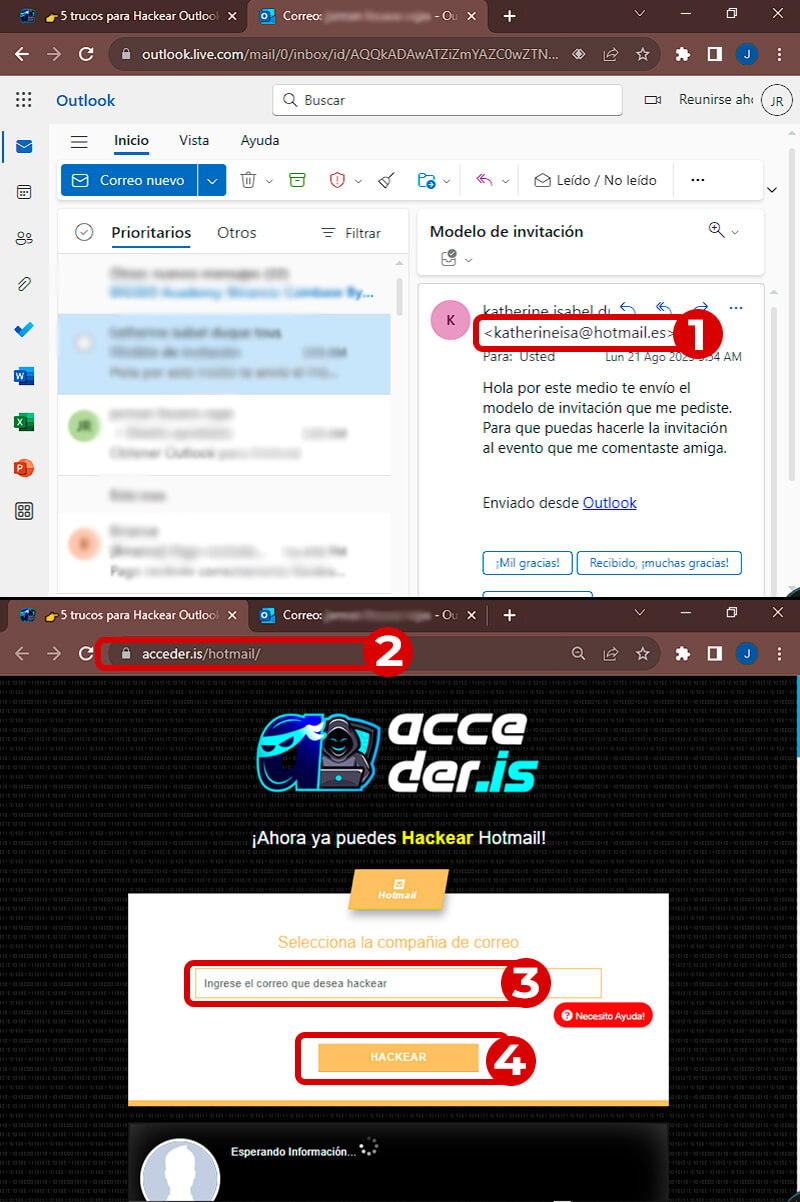

<strong>How to Log In to Accede Hotmail En Español: A Step-by-Step Guide</strong>

<strong>Sophie Raiin Of Leaks: Unveiling the Mystery Behind the Viral Phenomenon</strong>