Water for Injection vs. Sterile Water for Injection: The Critical Difference in Life-Saving Medical Use

Water for Injection vs. Sterile Water for Injection: The Critical Difference in Life-Saving Medical Use

In the sterile corridors of hospitals, pharmaceutical labs, and medical manufacturing facilities, two seemingly similar water types play pivotal but distinct roles: Water for Injection (WFI) and sterile water for injection. Though both labeled as injectable, their production standards, regulatory classifications, and intended applications diverge significantly—differences that are not trivial when lives depend on treatment integrity. Understanding the nuances between these two water types is essential for healthcare providers, pharmaceutical engineers, and regulatory bodies committed to patient safety.

Water for Injection is far more than potable water treated to microbial limits; it is a precisely engineered fluid produced to meet the exacting demands of parenteral therapies. It undergoes rigorous purification processes—including reverse osmosis, deionization, and final sterilization via distillation or ultraviolet treatment—to eliminate virtually all organic and inorganic contaminants. This ensures zero microbial presence and minimal endotoxin content, making WFI the gold standard for IV drugs, parenteral nutrition, and sterile compounding.

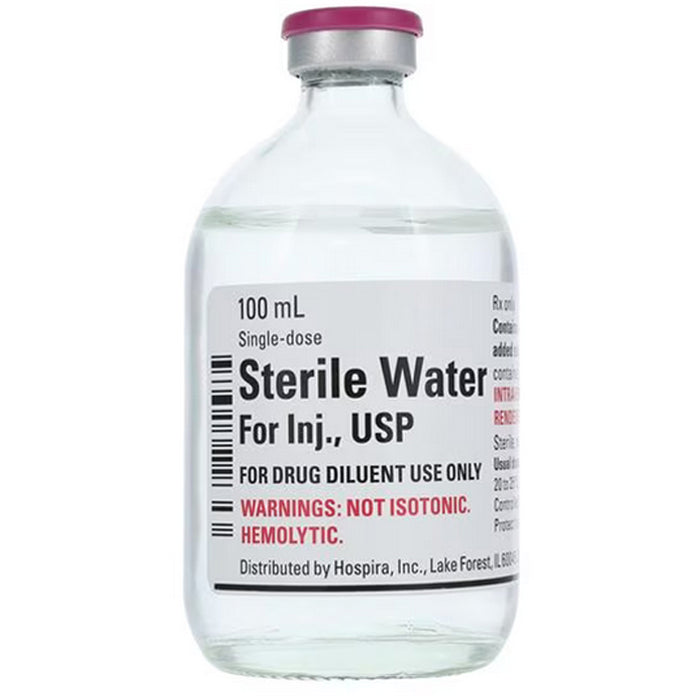

Sterile water for injection, while also intended for injection, operates within a slightly looser regulatory framework.

Defined as water that has been sterilized—typically through filtration (1.0 micron or smaller) followed by inertization with sodium bicarbonate or other agents—to achieve sterility with acceptable microbial limits. Though reliable for many non-parenteral injectables like diluent water for lyophilized vaccines or IV fluids in non-critical applications, sterile water does not meet the same sterility assurance level (SAL) or endotoxin thresholds as WFI.

The Science Behind the Sterility Differentiating

Water for Injection and sterile water for injection are both required by global pharmacopeias—primarily the US Pharmacopeia (USP <671>), European Pharmacopoeia (EP 2.7.14.1), and WHO guidelines—but with distinct sterilization end points. WFI systems incorporate continuous monitoring and validation protocols to maintain sterility and ensure endotoxin levels remain below 10 EU/mL, a threshold critical for preventing immune reactions during injection.

In contrast, sterile water for injection often relies on discrete filtration and inertization, achieving microbial count compliance (typically ≤100 CFU per liter for total aerobic microorganisms) but falling short of WFI’s stringent endotoxin requirements.

This disparity directly impacts clinical safety. For high-risk therapeutics—such as monoclonal antibodies, nucleic acid vaccines, or total parenteral nutrition formulations—any residual endotoxin or microbial metabolite can trigger febrile responses, inflammation, or severe hypersensitivity. WFI's ultra-pure profile minimizes these risks by eliminating or drastically reducing such contaminants.

In sterile water for injection applications, while safe for routine subcutaneous or intramuscular use, the slightly elevated endotoxin levels—though generally within passive UV or filter limits—pose minimal threat for most injectates but areえないunde ritoable in sterile injectables demanding maximum biologic fidelity.

Production Processes: Engineering Precision vs. Safe Simplicity

The treatment methodologies for WFI and sterile water diverge in both technology and purpose. Water for Injection is produced through multi-stage purification: first, raw water undergoes reverse osmosis to remove dissolved ions; then it passes through ion exchange and deionization to strip out organic contaminants; followed by distillation to vaporize impurities and UV oxidation to neutralize residual microbial spores and viruses.

This sequence ensures WFI meets not only microbial Sterility Assurance Level (SAL) 10-6—the gold standard—but also enforces endotoxin levels near zero.

Sterile water for injection, while still requiring rigorous filtration, typically stops at 0.1-micron filtration (NFE60 or equivalent) followed by terminal filtration or inertization to prevent recontamination. This process creates water sterile enough for many non-critical injectables but lacks the multi-barrier validation that defines WFI. For example, vaccines integrated with reconstituted powder formulations often demand WFI as diluent to preserve antigen stability, while sterile water suffices for dilute sterile solutions where endotoxin risk is negligible.

Regulatory Classifications and Pharmaceutical Applications

Globally, regulatory agencies distinguish these products through specific nomenclature and use conditions.

The USP references both Water for Injection (USP <666> for ordered supply) and Sterile Water for Injection (USP <589>), with the former requiring full sphericity validation, endotoxin limits, and microbial purity. Sterile water for injection, covered under USP <589>, is commonly labeled for bulk drug dilution or administrative use—applications where complete SAL 10-6 is not mandated but sterility remains non-negotiable.

In practice, medical professionals face real-world consequences tied to this distinction. A hospital compounding a life-saving monoclonal antibody requires WFI diluent to prevent protein denaturation and immune activation.

Using sterile water would not violate sterility limits but introduces inviable risk through undetected endotoxins or decay products. Meanwhile, a rural clinic administering a routine IV saline solution may use sterile water, safety preserved by contained risk. The choice is not merely technical—it’s clinical safety encoded in water chemistry.

Endotoxin Thresholds: A Matter of Risk and Reliability

Endotoxins—lipopolysaccharides from Gram-negative bacteria—pose specific dangers when injected.

Even trace amounts (1–10 EU/mL) can provoke acute systemic inflammation in patients receiving parenteral therapies. WFI’s distillation and UV-Steam processes virtually eliminate these endotoxins, whereas sterile water for injection passes through 0.1-micron filtration, allowing low-level tolerance. Though accepted in non-critical settings, this discrepancy underscores that WFI is a function of intent: maximum biologic safety.

Pharmaceutical formulations offer clinical insight. In oncology, where intravenous chemotherapy drugs demand subnanogram impurity limits, WFI is non-negotiable. A single endotoxin spike in a sterile water diluent could compromise an infusion but remains unacceptable for WFI-based biologics.

This isn’t revelation—it’s engineering: WFI’s treatment chains are calibrated to eliminate any biologic liability, making it the sole choice for high-stakes injectables.

Global Standards and Quality Variability

While WFI standards are tightly enforced by USP, EP, and ISO 14644-1 cleanroom benchmarks, regional quality can vary. In emerging markets, inconsistent monitoring of WFI systems often leads to intermittent failure in endotoxin control, creating risk even with officially labeled “sterile” water.

Conversely, in well-regulated facilities, continuous esterase testing and automated validation logs ensure WFI meets SAL 10-6 with near-perfect reliability.

Sterile water for injection, while bound by similar standards in regulated environments, lacks uniform enforcement, particularly in facilities without dedicated multi-stage purification. This creates a performance gap: a “sterile” water supply in one country may satisfy USP limits, while another may fall short, exposing patients in settings with weaker oversight.

The takeaway? Choice of water type demands not just compliance—but consistent validation.

The Unseen Foundation of Medical Care

Injection safety relies on the invisible backbone of water so pure it borders on science fiction.

Water for Injection and sterile water for injection are distinguished not by name alone, but by the depth of purification, test rigor, and intended clinical impact. WFI represents the pinnacle of injectable water purity—engineered for zero tolerance in life-critical biologics. Sterile water for injection serves a vital role, yet remains secondary in precision.

>The distinction is not academic—it is a frontier where water quality directly shapes treatment outcomes, patient trust, and global healthcare integrity. In the silent vats of pharmaceutical manufacturing and hospital compounding, every drop of WFI speaks a promise: safety through perfection. That promise cannot be compromised.

Against this silent standard, sterile water remains a margin of acceptable risk—useful, necessary, but not sufficient for the highest medical confidentiality of injectable care.

Understanding this duality empowers healthcare decision-makers to match water type to therapeutic demand, ensuring that what flows into a patient is not just liquid, but invincibly pure.

Related Post

Exploring The Enigma Of Drew Gulliver Nude: A Controversial Act At The Intersection Of Fame, Art, And Public Perception

How to Enter Your Activation Code & Activate Amazon Mytv Se with Precision

Subaru Impreza 2018 Hatchback: The Compact Essential with Enduring Appeal

How Social Media Girls Are Redefining Influence, Identity, and Connection in the Digital Age