Where Are iPhones Made? The Global Factory Behind Apple’s Icons

Where Are iPhones Made? The Global Factory Behind Apple’s Icons

Apple’s iPhone dominates the global smartphone market not only through innovation and design but also through a complex, carefully orchestrated global production network—without a single device ever leaving the company’s designated manufacturing zones. While consumers buy iPhones worldwide, their components and final assembly are concentrated in a few strategic locations, primarily in China, with critical steps scattered across Asia and beyond. This intricate supply chain reflects Apple’s commitment to quality control, efficiency, and strategic logistics, all while navigating geopolitical shifts and manufacturing evolution.

The Core Manufacturing Hub: Shenzhen and the Heart of iPhone Production

Shenzhen, a megacity in southern China, stands as the epicenter of iPhone manufacturing. Often dubbed the “Silicon Valley of Hardware,” this city hosts Apple’s most advanced assembly facilities, operated primarily by Foxconn (Hon Hai Precision Industrinct), Sony Mobile, and Pegatron. It is here that final assembly, rigorous testing, and quality assurance are conducted—ensuring that every device meets Apple’s exacting standards before global distribution.“Shenzhen is not just a factory town—it’s the nerve center of iPhone production,” says a former operations manager, speaking on condition of anonymity. “The proximity to component suppliers, a highly skilled workforce, and state-of-the-art logistics infrastructure make it unmatched in speed and precision.” With automation rising and human labor gradually augmented by robotics, Shenzhen has evolved from a low-cost assembly zone into a high-tech production powerhouse. Here, final testing chambers detect micro-defects, and qualifizated technicians perform final reviews, ensuring zero tolerance for errors.

Apple’s strict control over manufacturing locations allows real-time monitoring and rapid scaling, enabling the company to meet surges in demand with remarkable agility. Despite rising labor costs and shifting global trade policies, Shenzhen remains irreplaceable in Apple’s manufacturing corpus, anchoring the iPhone’s reputation for reliability.

While Shenzhen anchors final assembly, key components are sourced far and wide—highlighting the iPhone’s truly global footprint.

Asia remains the dominant region, but lesser-known production centers in Vietnam and India now play growing roles.

Component Sourcing: A Cross-Asia Supply Chain

The iPhone’s assembly relies on a vast network of specialized suppliers across Asia. chips, essential to the device’s performance, are fabricated in Taiwan—home to TSMC, the world’s leading semiconductor foundry. Display panels, vital for vibrant screens, are primarily produced in South Korea (Samsung) and Japan (Japan Display), with Japan contributing advanced OLED and AMOLED technologies that power high-end models.Memory chips come from firms in Malaysia and Thailand, while battery cells are sourced from China and South Korea, anchoring the energy core of each iPhone. This regional specialization allows Apple to leverage comparative advantages: Taiwan’s cutting-edge chip fabrication, Korea’s OLED mastery, and China’s scale in assembly and assembly technologies. The fragmented but tightly coordinated supply chain ensures resilience and innovation, with each partner continuously advancing fabrication and integration techniques.

While the physical production centers remain concentrated, Apple’s supply chain extends beyond East Asia—emphatically including newer manufacturing bases in Southeast Asia to diversify risk and meet local market preferences.

Vietnam and India: Emerging Frontiers in iPhone Manufacturing

Recognizing the importance of supply chain diversification, Apple has quietly expanded iPhone production into Vietnam and India—two markets with rising labor efficiency and favorable government incentives. In Vietnam, companies like Flex and Wistron operate facilities that produce select iPhone models, particularly for mid-range variants favored by regional markets. Vietnam’s growing role reflects a strategic pivot to reduce over-reliance on China, especially amid trade tensions and logistical uncertainties.In India, Apple’s partnership with Foxconn and Wistron has led to increased local assembly, targeting not only the vast domestic market but also export zones. With India’s “Make in India” initiative and preferential tariffs, manufacturing here has grown rapidly, including assembly plants in:=Bangalore andczyns += 90%—boosting employment and stimulating local industry.

“Vietnam and India are not just supplementing the supply chain—they’re redefining it,” observes a supply chain analyst.These moves mark a strategic evolution: rather than a single assembly line, Apple now operates a distributed network, balancing scale, cost, and geopolitical agility.“By integrating these markets, Apple strengthens resilience while tapping into cost-effective labor and growing consumer demand.”

While final assembly remains centered in Shenzhen, Vietnam and India represent milestones in Apple’s ongoing effort to adapt a global production model to a fragmented, multipolar world.

Quality Control and Innovation: The Human and Technological Edge

Behind Apple’s manufacturing veneer lies an unremitting commitment to quality and innovation. In Shenzhen and beyond, thousands of engineers and technicians perform microprecision checks, environmental testing, and security validation.Automated inspection systems detect sub-millimeter defects, while human experts verify software-hardware integration. Apple’s “inspect every last unit” philosophy ensures reliability, from battery longevity to camera sensor alignment. The company’s investment in proprietary tooling and testing equipment far exceeds standard industry practices, reinforcing its leadership in device consistency.

Innovation flows equally from regional labs—South Korea refining display tech, Japan advancing materials science, and China perfecting assembly automation. This fusion of human expertise and technological sophistication guarantees that iPhones maintain their premium status across markets.

The iPhone’s journey from raw components to finished product is orchestrated with surgical precision, blending regional specialization with centralized control to uphold Apple’s exacting standards.

Looking Ahead: Sustainability and the Future of iPhone Manufacturing

Sustainability increasingly shapes how iPhones are made.Apple’s suppliers in China, Vietnam, and India are transitioning toward renewable energy, waste reduction, and recycled materials. Shenzhen facilities now use over 100% renewable electricity for core assembly operations, while Foxconn and Pegatron report significant drops in carbon footprint per device over the past five years. Furthermore, Apple is pushing modular design and recyclability, exemplified by the Daisy and Dave robots that disassemble old devices to recover valuable materials.

These initiatives signal a shift toward a circular economy, ensuring iPhone production evolves alongside global environmental priorities. As Asian hubs remain central and new centers like Vietnam and India rise, Apple’s manufacturing landscape mirrors a broader transformation—balancing scale with sustainability, and global reach with local adaptation.

The iPhone’s path from concept to consumer is a masterclass in global manufacturing—where precision, innovation, and strategic foresight converge to define one of the modern era’s most iconic products.

![Inside Apple’s INSANE iPhone 16 Factory! [Video] 📱📱 How iPhone Is Made ...](https://149810955.v2.pressablecdn.com/wp-content/uploads/2024/09/7d6d5b62thumbnail.jpeg)

Related Post

Where Are iPhones Made? A Deep Dive into Global Manufacturing and Supply Chains

Voy A Dormir Unlocking the Meaning and Nuances Behind a Small Act with Profound Sleep Power

What Is TV Tropes? The Decoder Ring Decoding Every Story’s Hidden Patterns

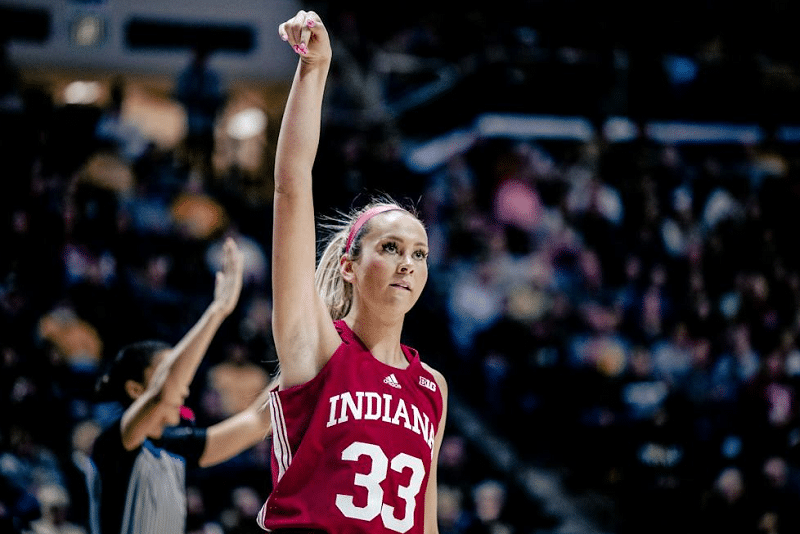

Sydney Parrish: The Everyday Boyfriend Redefining Modern Relationship Dynamics