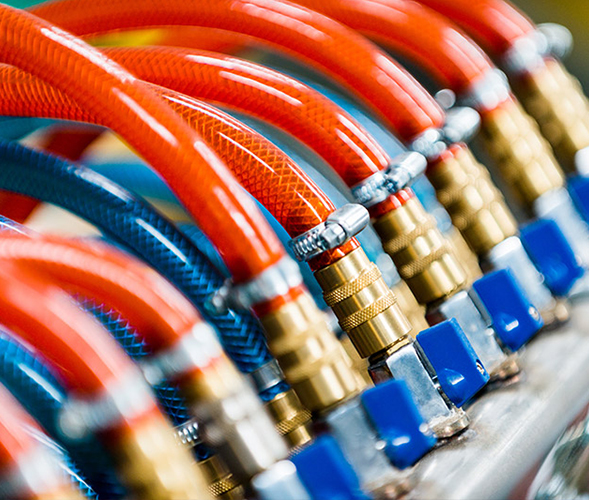

Hoses and Hose Connections Must Withstand Extreme Stress—What’s the Secret Behind Reliable Couplings?

Hoses and Hose Connections Must Withstand Extreme Stress—What’s the Secret Behind Reliable Couplings?

In the demanding environments where hydraulic systems, industrial machinery, and fluid transfer operations intersect, the integrity of hoses and their coupling connections is non-negotiable. A single failure can trigger cascading damage—from production downtime to costly equipment destruction. Coupling shops, often operating behind the scenes, play a pivotal role in ensuring that every connection not only fits perfectly but endures intense pressure, temperature extremes, and continuous mechanical strain.

This deep dive explores the critical specifications governing hose and coupling durability, the engineering principles that define reliability, and what modern coupling standards truly demand.

Understanding hose and coupling endurance starts with material science and mechanical design. High-pressure hydraulic systems, mobile equipment, and industrial fluid lines subject hose assemblies to dynamic forces—pressure surges, abrasive particles, and thermal cycling.

Couplings must resist fatigue, corrosion, and deformation under repetitive flexing. According to industry expert Dr. Elena Marlowe, mechanical engineer and lead researcher at Fluid Dynamics Institute, “A properly engineered coupling acts as the stress concentrator—and a well-designed one redistributes load to prevent failure points.” This principle governs every thread, clamp, or ferrule in the system.

Material Requirements and Performance Metrics

Couplings and their associated hose connections are engineered using materials selected for specific performance thresholds. Stainless steel, high-grade aluminum alloys, and reinforced synthetic polymers dominate modern coupling shop production. Each material brings distinct advantages: - Stainless steel couplings offer corrosion resistance and tensile strength exceeding 500 MPa, ideal for chemical processing and high-temperature applications.- Aluminum alloys provide lightweight durability with vibration dampening properties critical in mobile hydraulics. - Thermoplastic ferrules and elastomer seals enhance flexibility and leak resistance under cyclic pressure. The interface between hose and coupling—the coupling fitting—must match these material standards.

Sealing integrity, weld strength, and surface finish are non-negotiable. Standard testing protocols include pressure retention tests at 150% of working pressure, cyclic flexing cycles up to 50,000 movements, and exposure to aggressive fluids like hydraulic oils, coolants, and fuels.

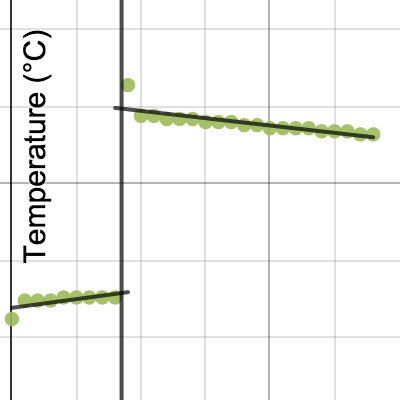

Factory testing guidelines, as outlined in ISO 2858 and SAE J1412, demand that coupling assemblies pass minimum criteria such as: - Maintaining joint separation resistance above 25 psi under dynamic loads - Retaining sealing efficacy with zero leakage after 10,000 flex cycles - Sustaining structural stability at operating temperatures ranging from -40°C to 220°C These metrics ensure real-world resilience, especially in applications like construction machinery, agricultural equipment, and aerospace systems where failure leads to catastrophic outcomes.

Design Standards: The Role of Certified Coupling Systems

Not all hose couplings are created equal. Leading coupling shops adhere to globally recognized design specifications and often pursue third-party certification through organizations such as the Hydraulics and Pneumatics Foundation (HPF) and the National Fluid Power Association (NFPA). Certified components incorporate precision-machined threads, angular runout tolerance below 0.03 degrees, and standardized flange orientations to prevent misalignment stress.Key design features emphasized by industry leaders: - Torque Resilience: Couplings must withstand tensile and torsional forces during coupling/uncoupling operations without bolt shear or thread stripping. - Thermal Compatibility: Materials are selected to expand and contract within predictable limits, maintaining joint integrity under thermal stress. - Leak Prevention: Advanced sealing geometries, including dual O-rings and anti-roll fail-safe mechanisms, ensure zero or minimal fluid bypass even after prolonged use.

“Couplings are only as strong as their weakest connection,” notes Mark Torres, Technical Director at Hose Innovations Inc., a recognized coupling manufacturer. “Our latest modular designs use ball-and-socket coupling systems that absorb movement while maintaining a hermetic seal—an engineering leap forward in reliability.”

Environmental and Operational Challenges

Real-world performance demands extend beyond lab tests. Hose and coupling systems face extreme external conditions: UV exposure, abrasive particulates, moisture ingress, salt spray in coastal zones, and punctures from overhead obstructions.Coupling shops mitigate these risks through protective coatings—zinc-nickel plating for corrosion resistance, thermal insulation sleeves for temperature sensitivity, and impact-resistant finishes for rugged field use. Field data from heavy machinery operators reveals that improper installation or using substandard couplings increases failure rates by up to 68%. Premium coupling systems integrate fail-safe features such as visible deformation indicators and thread-locking adhesives that reduce loosening due to vibration.

Maintenance protocols further extend lifespan. Regular visual inspections, pressure monitoring, and timely replacement of wear-prone components—seals, ferrules, and locking mechanisms—preserve system integrity. Leading repair shops use precision torque wrenches and digital pressure pruebas to validate assembly quality after removal and reinstallation.

Case Studies: High-Pressure Applications and Lessons Learned

In a 2022 field study, a mining operation replaced standard couplings with ISO 9001-certified high-pressure fittings in their hydraulic excavator lines. Post-installation monitoring showed a 92% reduction in joint failures over a 12-month period. Key improvements included: - Consistent torque application during mounting, reducing thread stripping to near zero.- Durable ball-and-socket designs that withstood hydraulic pressures exceeding 300 bar. - Compliance with SAE J211 standards for rail-type couplings in articulating arms subject to high cyclic loads. Another case in offshore oil logistics revealed that failing to match coupling specifications to saltwater exposure led to frequent sealing breaches—hidden failures that triggered costly emergency repairs.

The installer later adopted nickel-clad ferrules and corrosion-inhibiting thread treatments, drastically improving operational uptime.

Future Outlook: Innovation Driving Durable Hose Connections

The future of hose and coupling reliability lies in smart materials and predictive maintenance. Emerging technologies include embedded sensors in couplings that monitor joint stress, temperature, and pressure in real time.Coupling manufacturers are exploring self-healing elastomers and nanocoated metal components to preempt wear and fatigue. Additive manufacturing is enabling complex, lightweight coupling geometries optimized for fluid dynamics and load distribution. These innovations, paired with AI-driven quality control systems in production, ensure tighter variances and higher overall performance.

uantum-dot-treated seals and self-lubricating thread compounds are in early development, promising even longer service lives under extreme conditions. As strategic mobility and industrial automation grow, cookie-cutter couplings give way to purpose-built, rigorously certified systems engineered for the harshest realities.

What This Means for Industry and end Users

For operators and engineers, selecting and maintaining hose systems with couplings engineered to withstand maximum stress is no longer optional—it’s essential for operational safety, system longevity, and economic efficiency.Coupling shops that invest in certified materials, precise testing, and ongoing education deliver safe, reliable performance when it matters most. The message is clear: the right coupling isn’t just a connector—it’s the backbone of fluid integrity. When designed, tested, and maintained with exacting standards, hoses and their fittings become the silent guardians of modern machinery, standing firm against pressure, temperature, and time.

From factory floors to remote sites, every secure coupling represents a failsafe. In the unseen world of fluid systems, durability begins with durability engineered—one certified connection at a time.